Is your business ready for tomorrow's customer expectations

Customer expectations are on the rise, making it increasingly challenging to maintain a strong market position. Handling daily changes in item availability and resource capacity, as well as managing rush orders, are just some of the challenges that attribute-based manufacturing companies face.

Regardless of whether you excel in customer intimacy, product leadership, or operational excellence, what sets you apart today risks becoming the market standard in a short time.

Key challenges of attribute-based manufacturing

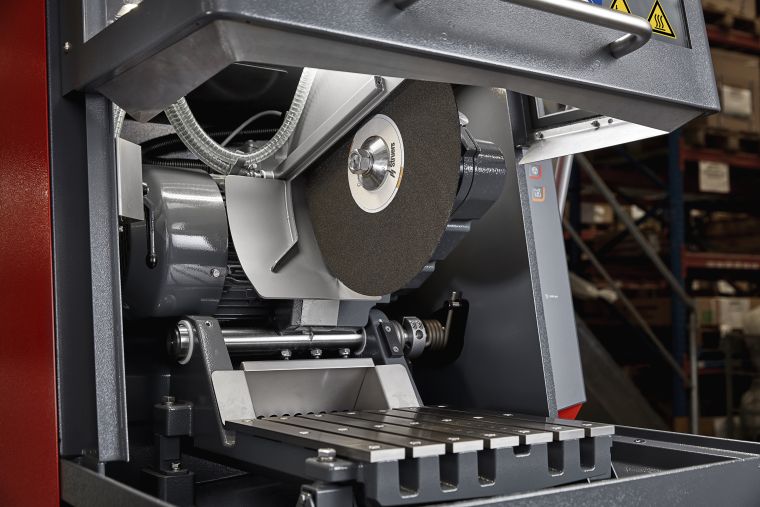

Maximizing operational efficiency

Navigating attribute-based manufacturing entails addressing multifaceted challenges. From accommodating design and delivery modifications to gaining operational insights and maintaining quality, every aspect demands meticulous attention.

Flexibility, operational insights, stockkeeping, and quality maintenance are key focal points within this manufacturing approach. Success hinges on a robust digital infrastructure fostering real-time visibility and data-driven decision-making. By synchronizing operations, your organization can thrive amidst modern manufacturing complexities.

.jpg?width=320&crop=0%2C0%2C4256%2C2832&mode=crop&format=jpeg&dpr=1.0&signature=6246579825de8831329dcf7306c4672737bb2b3d)

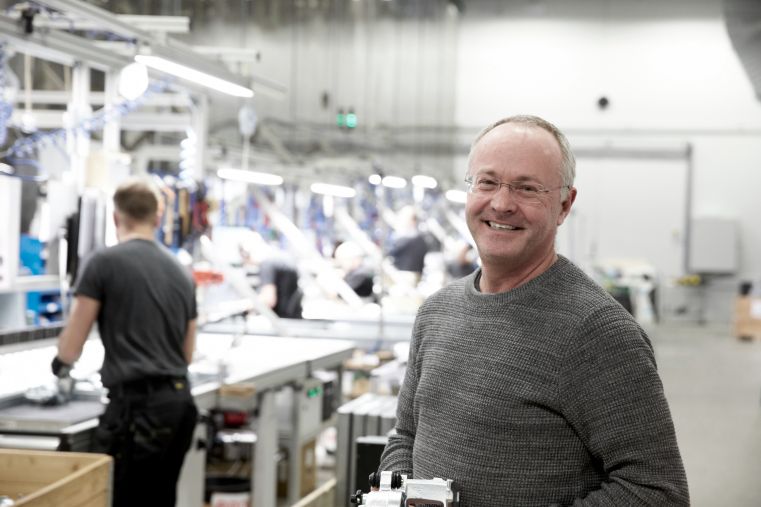

Mastering challenges in attribute-based manufacturing

Many manufacturing companies experience a evolution in their business model. E.g. going from standardized products towards attribute-based activities. The journey can be challenging, and it's imperative, that your process and people get the right support.

Your company's footprint is both affected by your direct and indirect actions - how do you e.g. take raw material's CO2 footprint into account in your purchasing process? This is just one example of situations, where the right internal system should support your business processes.

Seize control of digital common thread within your organization.

Your business is unique, molded by your business model, product, market dynamics, and team. All these factors play a crucial role in shaping your digital transformation journey. We're prepared to support your organization with solutions tailored to your distinct requirements. Whether you need strategic guidance for digital transformation or assistance with specific applications, we're here to help. Ready to kickstart your journey and scale to new heights securely? You've got it. We've got your back.

Dive deeper in the solution you are looking for:

.jpg?width=320&crop=0%2C107%2C2508%2C1434&mode=crop&format=jpeg&dpr=1.0&signature=1035752a00a36ffa66c4f49ea3544d69abd3fdda)

Are you leveraging AI in your manufacturing company?

Manufacturing operations generate vast amounts of data. By employing Artificial Intelligence (AI) to analyze these datasets, companies can uncover insights and trends, leading to substantial improvements. This scenario illustrates just one way AI can be harnessed to enhance your manufacturing business.